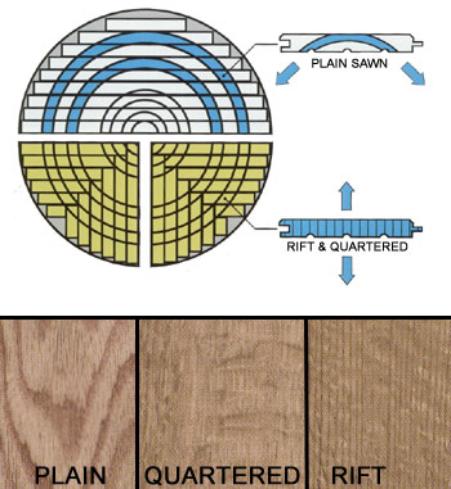

Just how a log is cut into lumber has a large influence on the quality of the finished product. When a sawyer saws a log, usually the goal is to obtain the largest volume of usable wood in the shortest length of time. This results in mostly plane sawn lumber that services the high volume wood industry. Quarter sawing (see digram below) produces boards cut on the radius rather than on the tangent (plane sawn). It is slower to produce at the sawmill but does result in a higher quality product. Quarter sawn wood has two distinct advantages over plane sawn wood.

• Structurally it has a much higher level of dimensional stability during the drying process and its life thereafter. In other words it is much less likely to bow, warp, or twist. And it is stronger.

• In addition to the structural advantages, many species display a beautiful pattern of rays that is sought after by woodworker's and cabinetmakers.

If you require dimensionally stable wood for glued up panels, tabletops or any cabinetwork that requires stability and beauty, quarter sawn will result in the highest quality finished products.

CUTTING BOARDS FROM A LOG

The methods of cutting wood are determined by the intended use, appearance, and stability of the wood. There are three cutting methods, of which the first two are the most common. Plane Sawn, Quarter Sawn and Rift Sawn.

Plane Sawn

This is the simplest method. The log is squared and sawed lengthwise. Knots that occur are round or oval -shaped and have relatively little weakening effect on the lumber. The annual rings appear as approximately straight lines running across grain. The lines join at the bottom, forming a U-shape; however, this part is sometimes cut off. Wood cut this way shrinks and swells very little in thickness.

Quarter Sawn

Wood cut by this method is called "quarter sawn if it is hardwood. If it is softwood it is called "edge grained" or "vertical grained". The log is sawed into quarters, then into boards. The angle between the cut and the growth rings varies from 90 degrees to about 45 degrees. In such wood, the lines formed by the rings run with the grain. Again they will appear as relatively straight or as U-shaped, depending upon how much is cut off. Such lumber shrinks and swells less in width and warps less than plain-sawn lumber.

Rift Sawn

The logs are sawed at not less than 35 or more than 65 degrees to the annual rings, usually at about 45 degrees. In wood sawed this way, the rings appear as longitudinal lines. Rays always run longitudinally and are longer than lumber cut by the other methods.

Advantages and Disadvantages of these Sawing Techniques:

Plan or Flat Sawn Quartered or Rift Sawn

1. Less waste but less stable. 1. Most waste and most expensive.

2. Less time cutting. 2. Most stable but narrow widths.

3. More shrinkage in width. 3. Shrinks more in thickness than width.

4 Less expensive. 4. More labor intensive.

5. Wider widths.

Which Method Should I use?

Well this really depends on your taste and on your project and maybe even your budget.The quarter sawn boards From an Oak tree will have the characteristic "Tiger Stripes" found only in quarter sawn lumber and will generally have less movement (shrinkage) when drying. The way the cells are aligned will cause the quarter sawn board to shrink a little bit in width and very little in thickness. Quarter sawn boards are also much less prone to warping.Plain sawn boards have grain in multiple directions, this will cause un-even drying and in turn cause the board to warp (cup, twist, and bow). The shrinkage rate is also much more pronounced in plain sawn boards. Due to the grain's orientation in the board, the board will shrink considerably in thickness as well as width.Again, the quartered lumber will mainly swell in width, and the plain sawn lumber will swell in width and thickness and possibly even warp.Besides the stability, (and sometimes ray fleck that is displayed), another great feature of quarter sawn lumber is if you have to glue up boards for a larger sized panel the grain is easily matched to look seamless.With proper precautions taken during assembly (using joinery that will allow slight seasonal movement of the wood), you can use either quarter sawn or plain sawn lumber in your project and have a beautiful piece of furniture that will last for generations.